Fuel line insulation is often overlooked in the quest for high performance in UK cars. Proper insulation safeguards against heat, moisture, and potential damage, ensuring optimal fuel delivery. With performance cars, every detail matters, especially when it comes to maintaining efficiency and longevity. Our tips will help you choose the right materials and techniques, enhancing your vehicle's performance while protecting your investment. Unlock the secrets to effective fuel line insulation and keep your car running smoothly.

Importance of Fuel Line Insulation

Fuel line insulation plays a critical role in enhancing vehicle performance and safety. By reducing heat exposure, insulation helps maintain optimal fuel temperature, ensuring efficient combustion and improved engine performance. This enhancement is particularly beneficial in high-performance vehicles where maintaining consistent fuel temperature is crucial.

Also to read : Mastering Headlight Alignment for Classic British Cars: A Complete Guide to UK Road Compliance

Performance Enhancement through Insulation

Insulating fuel lines can significantly boost a vehicle's performance. By minimizing heat transfer, it prevents fuel from vaporizing prematurely, which can lead to engine knock and reduced power. This ensures that the fuel remains at a stable temperature, allowing for more precise fuel injection and combustion. As a result, vehicles experience smoother acceleration and better fuel efficiency.

Safety Implications

Safety is another key benefit of fuel line insulation. Excessive heat exposure can lead to fuel vaporization, increasing the risk of vapor lock and potential fuel leaks. Insulation acts as a barrier, reducing these risks and enhancing the overall safety of the vehicle.

Also to discover : Mastering Air Suspension Setup for Your British SUV: A Guide to Conquering Any Terrain

Regulatory Considerations

In the UK, regulatory standards emphasize the importance of proper fuel line modifications. Compliance with these regulations ensures that any insulation used meets safety and performance standards. It is essential for vehicle owners and manufacturers to adhere to these guidelines to avoid legal issues and ensure optimal vehicle operation.

Materials for Fuel Line Insulation

Choosing the right insulation materials for fuel lines is crucial for achieving optimal performance and safety. Several materials are commonly used, each with unique properties and benefits.

Common Insulation Materials

-

Foam Insulation: Known for its lightweight and flexible nature, foam insulation is easy to install and provides excellent thermal resistance. It's particularly effective in reducing heat transfer, making it a popular choice for many vehicles.

-

Heat Wraps: These are designed to withstand higher temperatures and offer superior protection against extreme heat. Heat wraps are often used in high-performance vehicles where heat management is critical.

Factors to Consider

When selecting insulation materials, consider factors such as thermal resistance, durability, and ease of installation. It's also important to assess the vehicle's specific needs, such as operating temperature ranges and environmental conditions.

UK Market Availability

In the UK, a variety of insulation materials are readily available, catering to different vehicle types and performance requirements. It's essential to ensure that the chosen materials comply with local regulations and standards, ensuring both safety and efficiency.

Techniques for Insulating Fuel Lines

Understanding the best practices for fuel line insulation techniques is essential for both performance enhancement and safety. Proper application begins with selecting the right material for the vehicle's specific needs. Once chosen, ensuring complete coverage is crucial to minimize heat exposure and maintain optimal fuel temperature.

To achieve effective insulation, it's important to secure the material tightly around the fuel lines. This prevents any movement that could lead to gaps, which might compromise the insulation's effectiveness. Techniques such as using clamps or adhesive tapes can be employed to hold the insulation in place securely.

Additionally, overlapping the insulation material can help ensure thorough coverage. This practice reduces the risk of any exposed areas that could lead to heat transfer, thus maintaining the fuel's stability. For high-performance vehicles, where heat management is critical, employing a combination of insulation materials like foam and heat wraps can offer superior protection.

By focusing on these fuel line insulation techniques, vehicle owners and manufacturers can enhance both the performance and safety of their vehicles. Properly insulated fuel lines not only improve fuel efficiency but also reduce the risk of vapor lock and fuel leaks, ensuring a safer driving experience.

Installation Process Overview

Installing fuel line insulation is a straightforward process that can greatly enhance vehicle performance and safety. To begin, gather the necessary tools and equipment, including insulation material, clamps, adhesive tapes, and a cutting tool.

Step-by-Step Guide

-

Preparation: Start by cleaning the fuel lines to ensure there are no contaminants. This helps the insulation adhere properly and function effectively.

-

Measurement and Cutting: Measure the length of the fuel lines to determine the amount of insulation needed. Cut the insulation material accordingly, ensuring you have enough to cover the entire line with some overlap.

-

Application: Wrap the insulation tightly around the fuel lines, making sure there are no gaps. Overlapping the material slightly can help prevent heat transfer.

- Securing: Use clamps or adhesive tapes to secure the insulation in place. This prevents movement that could lead to exposure and inefficiency.

Tools and Equipment

- Insulation material (foam or heat wrap)

- Clamps or adhesive tapes

- Cutting tool

Common Pitfalls

Avoid leaving gaps in the insulation, as this can lead to heat exposure and reduced performance. Ensure the insulation is securely fastened to prevent it from shifting during vehicle operation.

Troubleshooting Common Issues

Understanding how to address fuel line insulation troubleshooting can greatly enhance vehicle performance and safety. Recognising signs of inadequate insulation is crucial. Look for symptoms such as engine knock, reduced fuel efficiency, or increased engine temperature. These indicate that the insulation may not be effectively preventing heat transfer.

Identifying Signs of Inadequate Insulation

Inadequate insulation often results in fuel vaporization, leading to engine knock and power loss. If you notice a decline in performance or unusual sounds, inspect the insulation for gaps or damage. Regularly checking for wear and tear can prevent these issues.

Solutions for Common Installation Mistakes

Common mistakes include leaving gaps or not securing the insulation properly. To rectify this, ensure the insulation is tightly wrapped and secured using clamps or adhesive tapes. Overlapping the insulation material can also help eliminate gaps, enhancing its effectiveness.

Assessing Insulation Effectiveness

To evaluate the effectiveness of the installed insulation, monitor the vehicle's performance and temperature levels. Use a temperature gauge to ensure that the fuel lines remain within optimal temperature ranges. Consistent performance and stable temperatures indicate that the insulation is functioning correctly. Adjustments may be necessary if fluctuations are observed.

Performance Benefits of Insulation

Fuel line insulation offers substantial performance benefits by enhancing fuel efficiency and engine performance. By maintaining a stable fuel temperature, insulation ensures optimal combustion, leading to smoother acceleration and increased power output. This stability is crucial in preventing engine knock and reducing fuel consumption, ultimately improving the overall driving experience.

Impact on Fuel Efficiency and Engine Performance

Insulated fuel lines prevent premature fuel vaporization, ensuring that the engine receives a consistent fuel supply. This consistency allows for precise fuel injection, which enhances combustion efficiency and boosts engine performance. As a result, vehicles benefit from improved fuel economy and reduced emissions, making insulation a cost-effective upgrade for long-term savings.

Case Studies Highlighting Improvements in Performance Metrics

Numerous case studies demonstrate the significant performance improvements achieved through fuel line insulation. For instance, high-performance vehicles equipped with insulated fuel lines have shown a marked increase in horsepower and torque, alongside enhanced throttle response. These metrics highlight the tangible benefits of insulation in real-world scenarios, reinforcing its value for both everyday and performance-focused vehicles.

Long-term Benefits of Maintaining Insulated Fuel Lines

The long-term benefits of maintaining insulated fuel lines extend beyond immediate performance gains. By reducing thermal stress on the fuel system, insulation prolongs the lifespan of fuel components, decreasing maintenance costs and enhancing vehicle reliability over time.

Safety Enhancements Through Insulation

Fuel line insulation significantly contributes to fuel line safety improvements, particularly in high-performance vehicles. By acting as a barrier against excessive heat, it reduces the risk of fuel vaporization, which can lead to dangerous situations such as fires. This is especially crucial in performance vehicles, where engines operate at higher temperatures, increasing the likelihood of fuel-related hazards.

In high-temperature applications, the importance of insulation cannot be overstated. It ensures that fuel remains at a stable temperature, preventing vapor lock and potential leaks. This stability is vital for maintaining the integrity of the fuel system and enhancing overall vehicle safety.

In the event of an emergency, understanding protocols related to insulated fuel lines is essential. Regular inspections should be conducted to check for signs of wear or damage. If any issues are identified, they must be addressed immediately to prevent safety hazards. Moreover, having a clear emergency protocol in place ensures that any potential risks are mitigated quickly and effectively, safeguarding both the vehicle and its occupants.

Ultimately, investing in proper fuel line insulation is a proactive measure that enhances safety, providing peace of mind for drivers and vehicle owners alike.

Compliance with UK Regulations

Navigating UK Automotive Regulations is essential for anyone involved in vehicle modifications, especially concerning fuel lines. These regulations are designed to ensure safety and performance standards are consistently met across all vehicles. Understanding the specific rules affecting fuel lines is crucial for compliance and avoiding potential legal issues.

Overview of Relevant Regulations

In the UK, regulations focus on maintaining vehicle safety and environmental standards. This includes ensuring that any modifications, such as fuel line insulation, do not compromise these aspects. Insulation must meet specific thermal resistance and durability criteria, as outlined by UK standards.

Insulation's Role in Compliance

Fuel line insulation plays a vital role in adhering to safety standards. By maintaining stable fuel temperatures, it reduces risks associated with vaporization and leaks, aligning with regulatory safety requirements. Proper insulation ensures that vehicles operate efficiently within the prescribed safety margins.

Documentation and Reporting Requirements

Compliance with UK automotive regulations requires thorough documentation and reporting of any modifications. This includes detailed records of the materials used, installation processes, and any testing conducted to verify compliance. Keeping accurate documentation is essential for demonstrating adherence to regulations during inspections or audits.

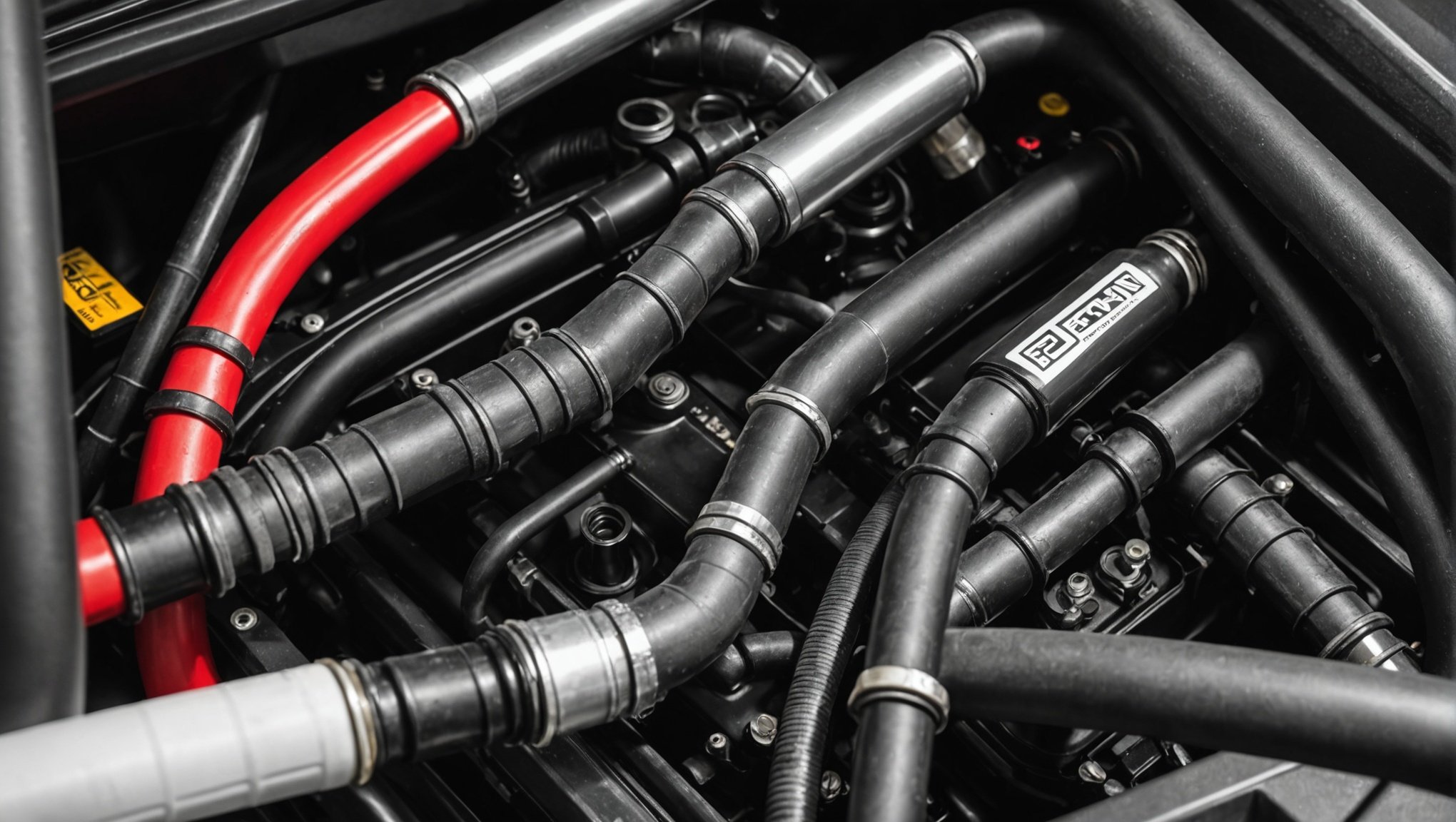

Visual Aids and Diagrams

Visual aids and diagrams are invaluable tools for grasping the intricacies of fuel line insulation. They simplify complex installation steps, making the process more accessible for both professionals and DIY enthusiasts. By providing clear, visual representations, these aids help users understand the correct application techniques, ensuring effective insulation.

Importance of Visual Aids

Visuals offer a step-by-step guide that complements written instructions, reducing the likelihood of errors. They highlight key areas where mistakes commonly occur, such as leaving gaps or improper securing of the insulation. This clarity is crucial for achieving optimal performance and safety.

Examples of Effective Setups

Effective fuel line insulation visuals demonstrate ideal setups, showcasing properly wrapped and secured lines. These examples serve as benchmarks for users, illustrating the desired outcome of a well-insulated fuel line. By comparing their work to these examples, users can identify and correct any discrepancies.

Diagrams Illustrating Mistakes and Corrections

Diagrams are particularly useful in highlighting common mistakes and their solutions. They visually depict errors like insufficient overlap or loose insulation, alongside corrective measures. This guidance helps users rectify issues promptly, ensuring the insulation functions as intended and maintains fuel line integrity.

Community Resources and Support

The performance car community in the UK is a vibrant network where enthusiasts connect, share, and support each other. Online forums and groups are invaluable resources for those interested in fuel line insulation and other modifications. Platforms like PistonHeads and UKCarScene offer dedicated spaces for discussions, allowing members to exchange insights and experiences.

Online Forums and Groups

These online communities are treasure troves of information. Members frequently discuss the latest trends, share installation tips, and recommend products. For newcomers, these forums offer a supportive environment to ask questions and learn from seasoned enthusiasts who have hands-on experience with fuel line insulation.

Recommended Workshops and Professionals

Within the performance car community, there is a wealth of knowledge about local workshops and professionals who specialise in installing fuel line insulation. Recommendations are often based on personal experiences, ensuring that newcomers can find reliable services. These experts provide tailored solutions, ensuring compliance with UK regulations and enhancing vehicle performance.

Sharing Experiences and Tips

Community members actively share their successes and challenges, offering valuable insights into the practical aspects of fuel line insulation. By engaging with the performance car community, enthusiasts can gain confidence in their projects, leveraging collective wisdom to achieve optimal results.